Frequently Asked Questions

Below is a list of common questions concerning the project. If you have any other questions, feel free to contact Mohammad Ghashami at ghashami.m[at]gmail.comWhy LEGO® bricks?

LEGO® bricks are affordable, easy to use, and already played with by millions of people, making them an ideal base for development of a kit of this kind. Virtually all students have used LEGO® bricks before, making the construction of the model as easy as following the assembly directions. This is ideal so that the models can be constructed quickly and easily, with no complex or specially constructed components being used. In addition, the lack of complex and specialized components means if a part breaks or gets lost, fixing the model is easy and costs no more than a few dollars.

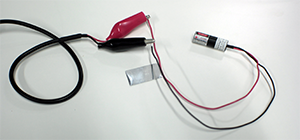

Is there anything not a LEGO® brick?

Only three components are not technically a LEGO® brick: A low power laser, a power supply for the laser, and a small reflective plate. The laser is a such a vital component to the AFM design and being that there is no LEGO® brick counterpart, must be taken from be an outside source. These components are so vital to the AFM operation, that they do not take away from the spirit of a LEGO® brick based model.

Is this really how an actual AFM Works?

Yes! The basic components of an AFM are present in the model and although they may be larger, the basic idea and interaction between these components are the same. Students who understand the operation of the model AFM understand the basic concepts of AFM.

To the right is a simplified model of an AFM, showing the major components that are also present in the LEGO® brick model. More information on the operation of an AFM can be found in the informational video and the Wikipedia article on AFM is a good resource.

To the right is a simplified model of an AFM, showing the major components that are also present in the LEGO® brick model. More information on the operation of an AFM can be found in the informational video and the Wikipedia article on AFM is a good resource.

Why do some of the scans look terrible?

There are a few factors that may contribute to a scan looking less than spectacular. Each factor manifests as a specific artifact in the final scan. Many can be fixed with an operational parameter, so see What are the operational parameters that can affect the scan? below for more information. Alternating rows are offset – Due to the fact that LEGO® motors are not as accurate as specialized robotic motors, there are some issues that may arise. One is due to the fact that the two motors may not rotate at the same speed or have the same power in the foward and backward directions. This means that in a scan, every other row being driven backward is offset to the other rows being driven forward. This effect is reduced by the gearing system but ultimately must be fixed manually with the runtime parameters. As each motor varies from one another and ages differently, a hardcoded value to correct this effect is not possible, so instead the operational factor Creep Correction is used.

Above is a scan with an incorrectly set Creep Correction factor. Discrete scan lines are visible and if drastic enough, can make it difficult to analyze the scan. This can be fixed by adjusting the Creep Correction until the scan rows line up. This occasionally needs to be adjusted between scans, as the motor characteristics change with use.

Background noise – The LEGO® MINDSTORM light sensors can be sensitive enough to show background noise when the cantilever drags along a flat surface. In addition, the sensors can be sensitive enough to register millimeter height differences of the scanning platform bricks. Thus, the operational parameter Noise Suppression is used to eliminate any background noise by ignoring any sensor readings below a set value.

Above is a scan with an incorrectly set Creep Correction factor. Discrete scan lines are visible and if drastic enough, can make it difficult to analyze the scan. This can be fixed by adjusting the Creep Correction until the scan rows line up. This occasionally needs to be adjusted between scans, as the motor characteristics change with use.

Background noise – The LEGO® MINDSTORM light sensors can be sensitive enough to show background noise when the cantilever drags along a flat surface. In addition, the sensors can be sensitive enough to register millimeter height differences of the scanning platform bricks. Thus, the operational parameter Noise Suppression is used to eliminate any background noise by ignoring any sensor readings below a set value.

Above is a scan with no noise suppression. Background noise is visible in blue and can make analyzing the scan difficult. By setting the Noise Suppression factor to a high enough value, this background noise will be eliminated.

Above is a scan with no noise suppression. Background noise is visible in blue and can make analyzing the scan difficult. By setting the Noise Suppression factor to a high enough value, this background noise will be eliminated.

Are the limitations the same as on an actual AFM?

Yes, many of the disadvantages of AFM are present in the LEGO® model. These factors are present in any “machine” that employs the AFM model of operation. Although in the real world these may be detrimental, in an educational model these disadvantages help increase the realism of the model and students can learn about these disadvantages as if they were using an actual AFM. Some disadvantages are:

- Distortions due to problems with the tip (the shape of the tip for example)

- Distortions due to problems with the surface (the distance between features for example)

- Improper filtering and signal artifacts

Wouldn’t the limitations of the model be overcome with something other than LEGO® bricks?

Using more precise components that are able to move uniformly as well as without twisting would certainly increase accuracy and remove some limitations. These limitations, however, mirror those in actual AFM setups, and thus are important to be taught to students. Furthermore, using more components that are not constructed of LEGO® bricks would be against the spirit of the project, which is constructing an easy to use and cheap kit to teach AFM basics. Since LEGO® bricks are cheap and widely available, the benefits outweigh the drawbacks.

What are the operational parameters that can affect the scan?

There are several parameters that can be changed before runtime from the LabVIEW interface. They are:

- Connection via USB or Bluetooth?

- The controller computer can connect to the NXT brick via a Bluetooth or USB connection. When using USB, although the NXT brick must be physically connected with a wire, the number of datapoints possible in a scan is higher than with Bluetooth. This is because the bandwidth available with USB is typically higher than with Bluetooth.

- Creep Correction

- Offset alternating rows by a set factor. This helps to eliminate the splitting of rows when the motor moves differently forward and backward.

- Y-Iterations

- Movement in the x-axis is determined by the operator. This number is the number of rows that should be scanned of the sample.

- Noise Suppression

- Any readings below this value will be interpreted as a zero. This helps with an inconsistent sample stage and small variations in the light sensor readings. Noise suppression helps clean up scans by ensuring a clean background sample.